Clock Repairs

Timemenders repairs all clocks using a standard process which requires a lot of skill, training and equipment. There are various clock types with multiple styles and systems, all repaired similarly.

The process involves:

- Removing the clock hands and taking the clock mechanics out of its case.

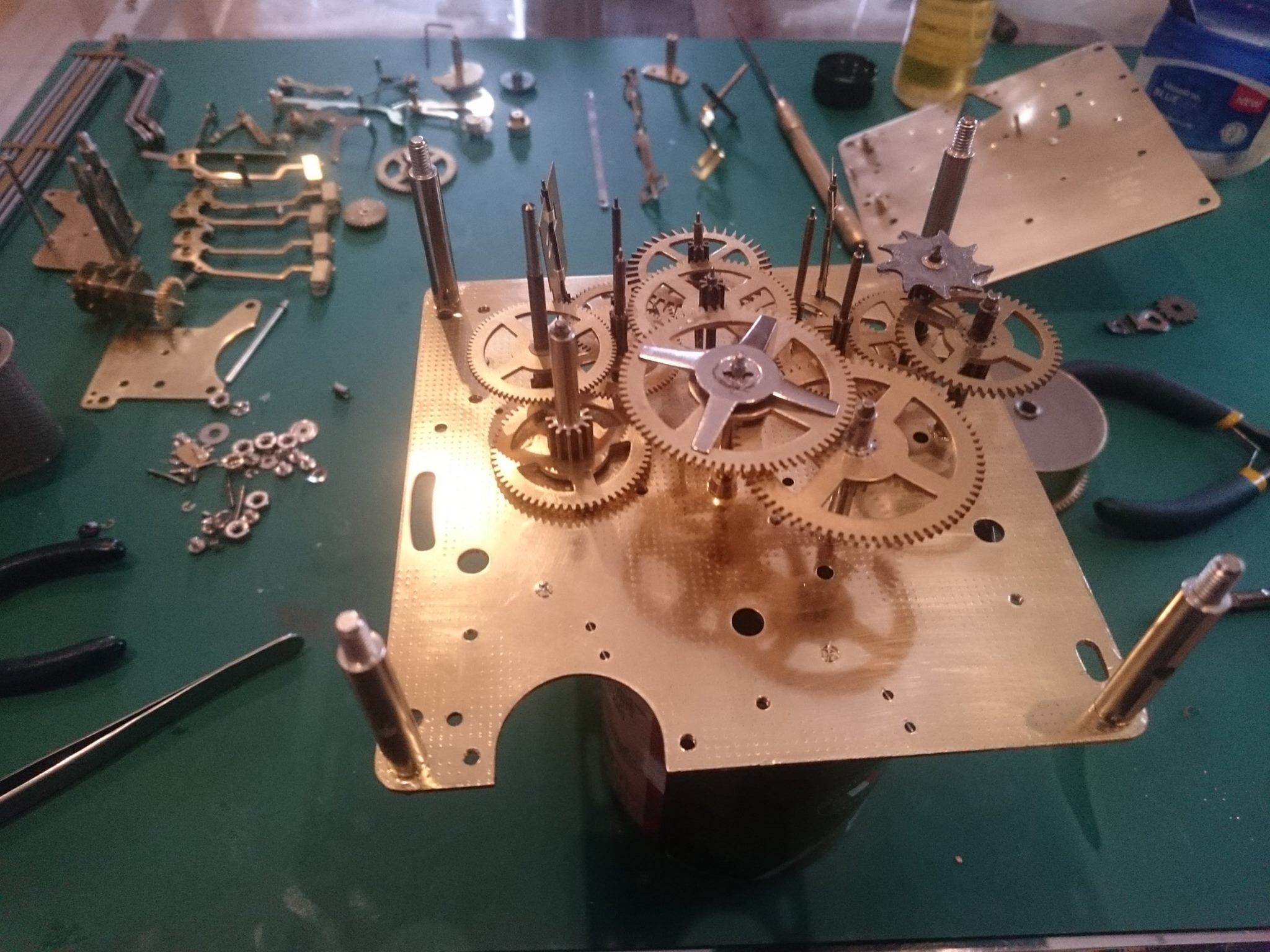

- Inspecting the clock mechanism and then disassembling.

- Cleaning all parts in a particular cleaning solution before rinsing and drying them.

- Checking all parts and rectify any faults. In most cases, we can manufacture replacement parts or repair damaged parts. If the clock is spring driven and there are issues with the springs, they are either repaired or replaced.

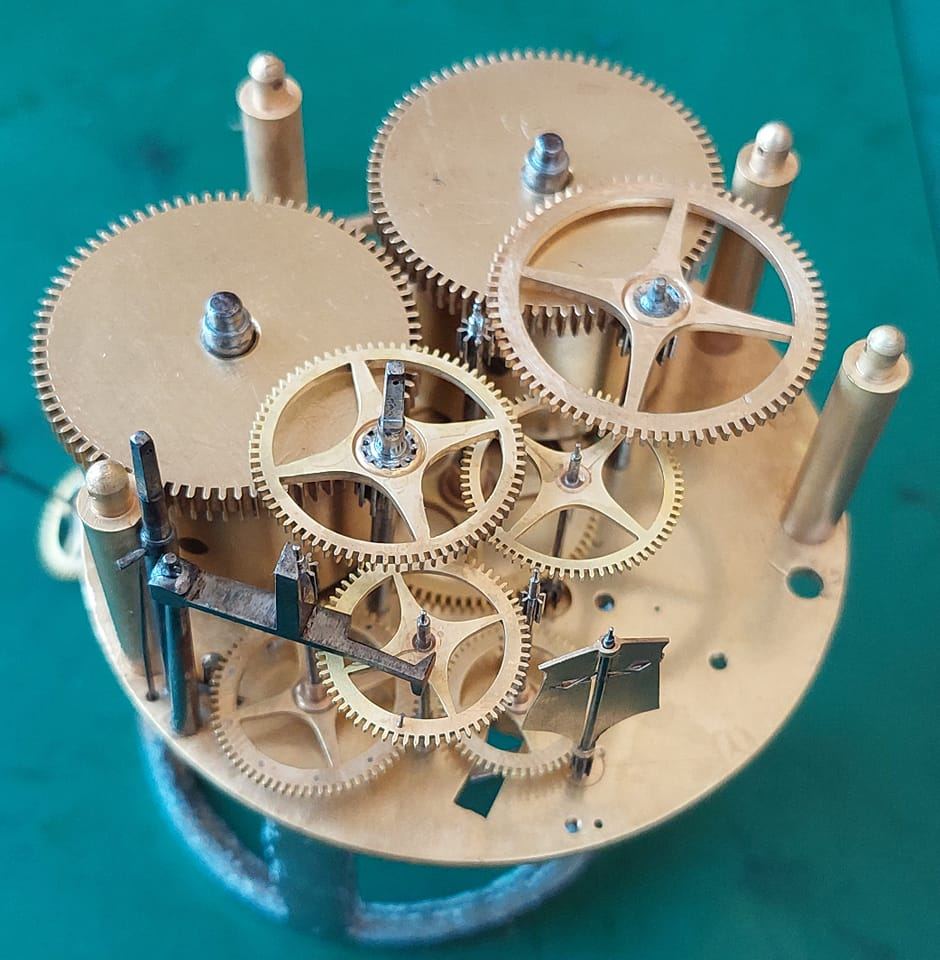

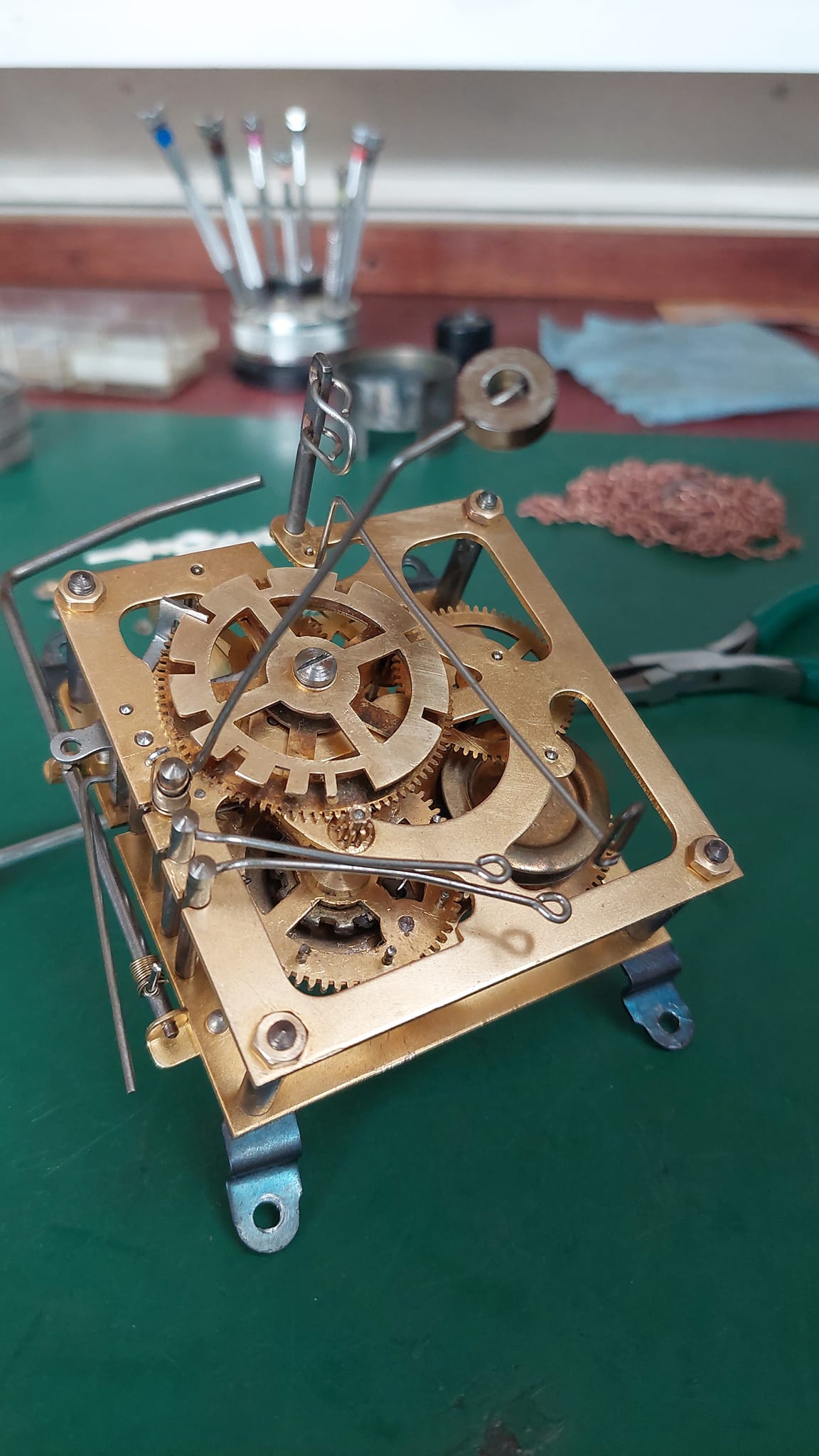

- Pre-assembling the clock, inspect the bushings and refurbish any worn bushing holes.

- Assembling the clock and set the timing.

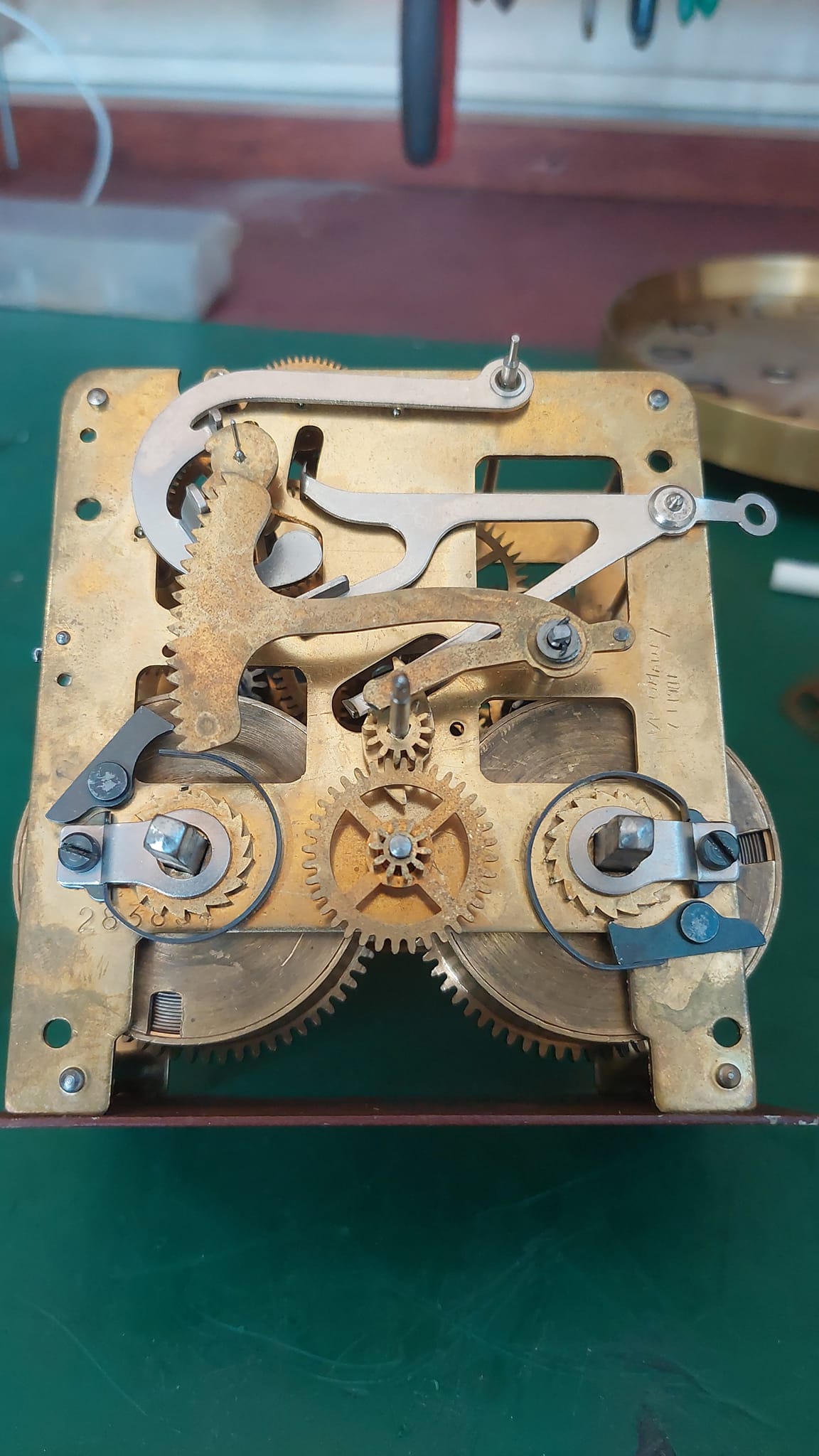

- Installing and checking all the clock levers and hammers. During this process, we add proper lubrication to the correct parts.

- Test-running and checking the mechanism over a period. In general, this is the duration the clock runs for. Most clocks run for eight days, but there are exceptions.

- Installing the dial and hands and set the timing.